Guide to Creating a Product Technical Sheet

The product technical sheet is an essential document for those in the fashion, design, and manufacturing sectors. This tool ensures that a product is created according to precise specifications, avoiding errors and optimizing production processes. In this guide, you will learn how to create a detailed and functional product technical sheet.

What is a Product Technical Sheet?

A product technical sheet is a document that gathers all the necessary information for creating a product, including measurements, materials, processing, and technical details. With this tool, manufacturers and suppliers can follow precise specifications, minimizing errors and improving the final product’s quality.

Why is a Product Technical Sheet Important?

Without a detailed technical sheet, the risk of production errors increases, leading to material waste, delays, and extra costs. It also helps standardize production, ensuring that every piece meets the required quality standards.

Main Types of Technical Sheets

There are different types of technical sheets depending on the industry and product type:

• Technical sheet for clothing: Includes details on fabrics, stitching, sizes, and finishes.

• Technical sheet for accessories: Specifies materials, dimensions, and assembly methods.

• Technical sheet for electronics: Describes components, technical specifications, and necessary certifications.

• Technical sheet for furniture: Details materials, dimensions, and finishes.

Need help creating your technical sheet? CLICK HERE to contact us for personalized consulting!

How to Choose the Right Technical Sheet for You?

The choice of the appropriate technical sheet depends on several factors, including:

• Product type: Each industry has specific needs, such as clothing requiring fabric and stitching details, while electronics must include technical specs and certifications.

• Company size: A small business might need a simpler, more flexible sheet, while a large company requires a more detailed document.

• Process automation: Using specialized software can make the management of technical sheets more efficient.

Advantages of a Fashion Technical Sheet for Your Manufacturing

The fashion technical sheet is an essential document in the production of clothing and accessories. Here are its main advantages:

- Clarity in instructions – Specifies the design, materials, measurements, and manufacturing techniques in detail, avoiding ambiguity in production.

- Error reduction – Provides precise information, reducing the risk of misunderstandings between designers, pattern makers, and manufacturers.

- Cost optimization – Avoids material and resource waste through detailed planning.

- Improved quality control – Allows verification of products against required standards.

- Easy communication – Helps coordinate work between various company departments and external suppliers.

How to Create a Fashion Technical Sheet

A fashion technical sheet must be clear, detailed, and complete to ensure accurate production of the garment. The document begins with a header including the brand name, model code, season reference, and creation date. Technical illustrations must depict the garment from various perspectives, highlighting seams, finishes, and other key details. The materials section describes fabric composition, weight, and color variants. Measurements and fit must be provided with precision for each size, including any production tolerances. The packaging instructions detail stitching, finishes, and additional elements needed for garment completion. Lastly, production notes specify required quantities and quality control procedures, ensuring consistency and accuracy throughout the production process.

How to Avoid Errors in the Fashion Technical Sheet

To avoid issues and delays in production, follow these tips:

- Be detailed and precise: Every piece of information must be clear and well-documented, leaving no room for interpretation.

- Use clear and readable images: Ensure that technical drawings are accurate and well-labeled.

- Double-check measurements: Verify size charts and compare them with prototypes to avoid inconsistencies.

- Use correct technical language: Avoid ambiguous terms and make sure instructions are understandable for the production team.

- Keep the document updated: If changes are made, ensure the sheet is updated and communicate the changes.

- Involve suppliers and the production team: Before finalizing the sheet, ensure that all specifications are feasible.

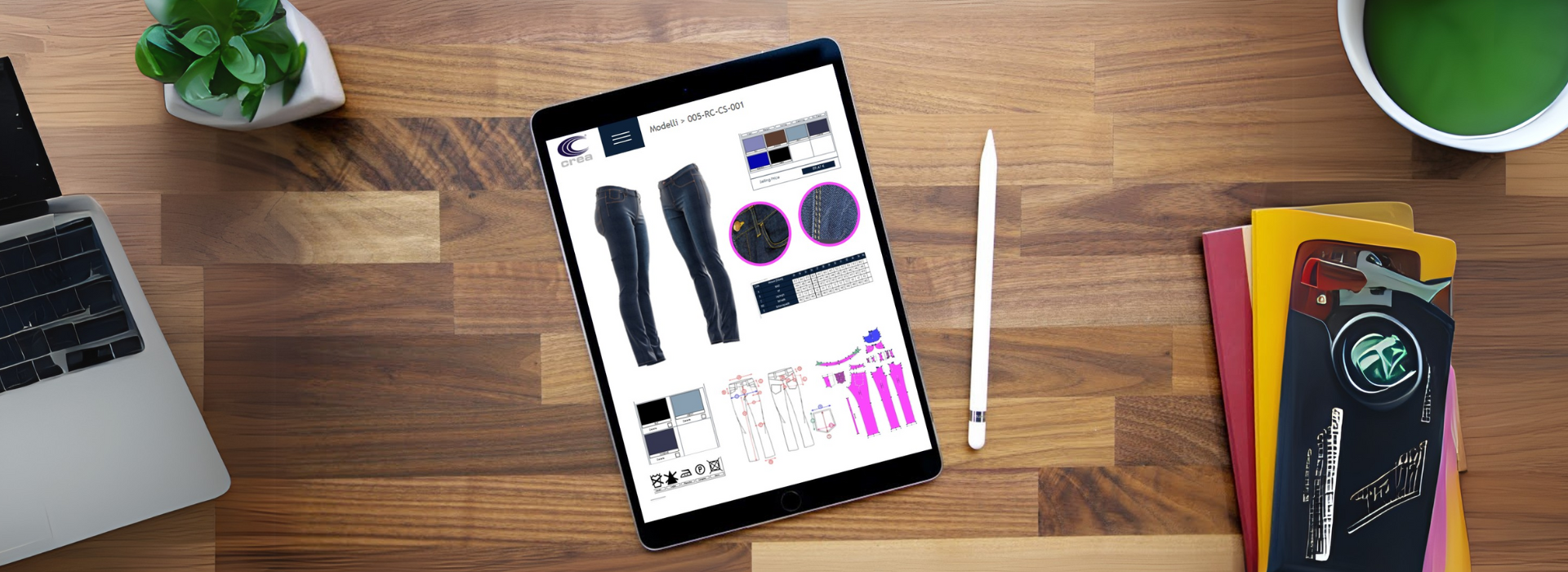

Automating the Creation of Technical Sheets: How?

There are dedicated software solutions for the automatic or semi-automatic creation of product technical sheets, tools that optimize and speed up the documentation process. These programs, such as PLM systems, allow companies to gather, organize, and precisely generate all necessary information about a product’s technical characteristics. By using these solutions, businesses can reduce manual errors, improve efficiency, and ensure more integrated management of product information, from design to commercialization.

The product technical sheet is a crucial element to ensure efficient and high-quality production. Creating a detailed sheet means reducing errors, improving communication, and optimizing costs. If you want to improve your company’s production process, start developing detailed technical sheets today!

Discover how to create a detailed and effective product technical sheet. CLICK HERE to improve production, reduce errors, and optimize costs with our complete guide!