CAD and CAM: What Exactly Do They Mean?

In the fashion world, technological innovation is revolutionizing every stage of the production process, from design to garment manufacturing. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems have become essential tools for fashion designers and pattern makers. The integration of these technologies is transforming the fashion industry, making it more sustainable, faster, and more competitive.

What Is CAD?

CAD stands for Computer-Aided Design. It allows you to develop patterns and collections digitally, reducing time and costs while increasing precision during the design phase. The primary goal of CAD systems is to support the design process by enabling the creation of virtual models that accurately represent the finished garment.

What Is CAD Used For?

3D CAD systems for pattern making are powerful tools for visualizing how garments will behave in the real world. These tools let you test different design options, materials, and fits without the need to physically create each sample.

Thanks to CAD, pattern makers can review and optimize designs, minimizing errors or last-minute changes during production.

What Is CAM and When Is It Used?

CAM stands for Computer-Aided Manufacturing. CAM automates production processes, such as fabric cutting, ensuring efficiency, quality, and reduced waste.

How Does CAM Work?

CAM systems use the data and patterns created with CAD to generate operating instructions for machinery, such as CNC (Computer Numerical Control) machines or cutting machines.

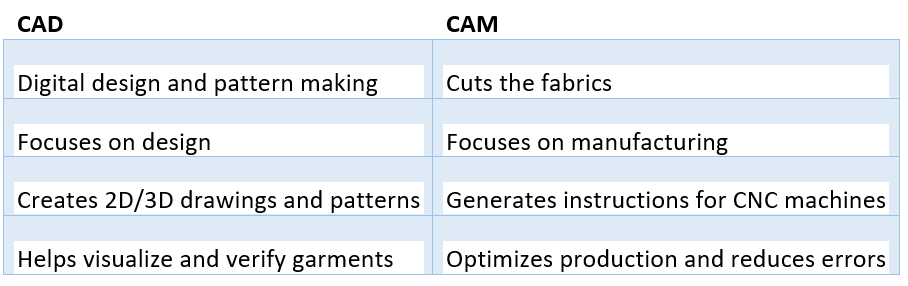

Difference Between CAD and CAM

Why Use CAM Instead of Manual Programming?

Using a CAM system offers many advantages over manually programming machine tools:

- Precision and Complexity

CAM makes it possible to manufacture complex components with a level of precision that’s hard to achieve manually. Manual programming takes much longer and increases the risk of mistakes. - Reduced Programming Errors

CAM software optimizes tool paths, minimizing human errors. This leads to higher quality finished products. - Tool Optimization

With automatically managed machining parameters, CAM helps reduce tool wear, extending the life of cutting equipment and lowering maintenance costs. - Reduced Waste

CAM optimizes material usage, limiting waste and improving production efficiency. - Automation and Time Savings

Automating processes reduces manual intervention, boosts productivity, and speeds up production times—ultimately increasing your company’s competitiveness.

Conclusion: Why CAD and CAM Are the Future of Manufacturing

CAD and CAM systems are now indispensable for companies looking to innovate, cut costs, and improve efficiency in both design and production processes. By integrating these tools, businesses can deliver higher-quality products, shorten development times, and optimize every phase of the production chain.

If your company is aiming to digitize its processes, CAD and CAM are the solutions you’re looking for.