CAD for Bags and Accessories: simple and fast design

“2017 was characterized – with reference to the global economic scenario – by an expansive phase in which the restart of manufacturing activities in many advanced and emerging countries played a decisive role, encouraging the resumption of trade. In Italy, the long-awaited trend reversal was very unevenly manifested, not only among the various production sectors, but also within the same sectors, with companies that are still struggling to experience significant improvements in orders and degree of use. of production capacity. The Italian leather goods sector – although not without reality, especially small and medium size, which have not yet embarked on the virtuous path of recovery – highlights overall, in the preliminary figures, dynamics fully in line with the positive evolution above dotted. It is estimated that the sector recorded an increase in turnover of around 6.4% in the first 10 months. “(Source: Economic note drawn up by the Confindustria Moda Studies Center)

A bag is a very personal accessory that reflects the style of the woman who wears it. The alternatives are varied, and you can range from small clutch bags to large bags, but what really matters is the selection of materials with which the various models are made.

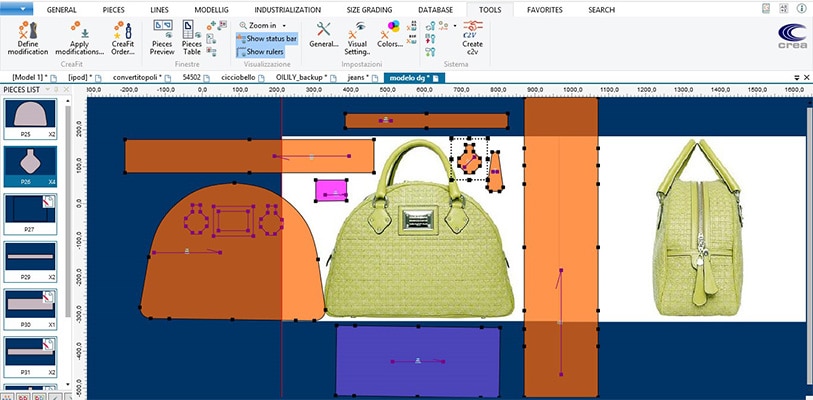

The creation of leather bags has always been a very delicate process due to the high cost of the raw material and its heterogeneous nature. Crea Solution offers solutions able to automate processes that until a few years ago needed the eye and human intervention. Thanks to the innovative artificial vision system it is now possible to detect the areas of quality and defect, place the model previously created with a CAD for bags and cut the pieces with extreme precision, without human intervention.

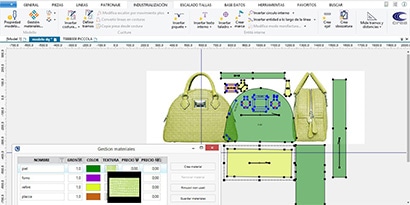

Create ™ bags is a CAD version designed and developed specifically to facilitate the design of objects in leather goods and bags. In this version there are particular features that give the possibility to create special symbols or punches, to perform a cylindrical development, to insert specific metal items within the design. It is also possible to define what will be the quality areas of the leather article so that this information will condition the automatic placement on the leather.

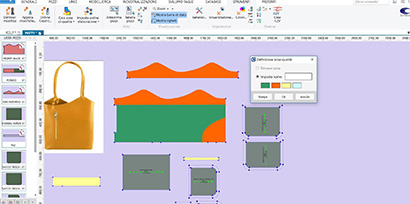

Here are some important features:

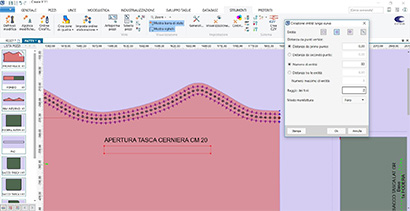

- A wide range of sewing steps.

- Control of notches, buttons, holes, wire guides, texts, lines, circles and other elements for editing and size grading.

- The definition of the fabric during the drafting and the placing of the pieces.

- The ability to recreate the fabric, through its relationship, or simply scan it.

- Total freedom in the colors and definition of the type of line for the objects, the pieces, the interiors, the stitching, the positioning.

- The ability to change each parameter with a simple mouse click during your work.

In order to reduce the consumption of fabric for the creation of bags up to 5%, it is now possible to exploit positioning algorithms that perform the perfect optimization of raw materials.

If the designed bags are made of leather, it is possible to define the quality zones of the parts of the model directly from the CAD, that is to give priority to certain pieces rather than others by simply assigning colors. It is therefore possible to assign the attribute “quality” on the internal lines, to give a geometric definition of the regions of a piece through direct line drawing, to define the quality level of the part through the type / code assignment and to manage this information in the form HPGL OUT.

This information will automatically pass to the automatic leather nesting algorithm that will optimize the nesting respecting the rules given by the pattern maker through a vision system. To do this it is necessary to scan the leather through the camera and then delineate the perimeter of the hides with assignment of particular codes to the raw material.

Through integrations with PLM, ERP and CAD systems for Crea Solution bags it is possible to consult the data collected during these scans and have a real reliability rating and ranking of raw material suppliers, analyze the quality, analyze the surface of the leather, obtain information regarding the location of the pieces for an order.