Fabric Cutting Machines: The Main Differences Between Single-Ply and Multi-Ply Systems

Fabric cutting machines are an essential solution in the apparel industry and technical sectors where cutting precision is crucial. Whether you work in Made to Measure (MTM) or industrial production, choosing the right cutting technology is key to achieving excellent results. In this article, we’ll explore the main differences between single-ply and multi-ply cutting machines, helping you identify the ideal solution for your production workflow.

What Are Fabric Cutting Machines?

Fabric cutting machines are automated systems that precisely cut a variety of materials, from simple fabrics to more complex technical textiles. These technologies have revolutionized the textile industry thanks to their efficiency, flexibility, and precision, reducing waste and optimizing production times.

The two main types of fabric cutting machines are:

Let’s take a closer look at the main differences between these two solutions.

Single-Ply Cutting Machines: The Perfect Choice for Pattern Matching and Prototyping

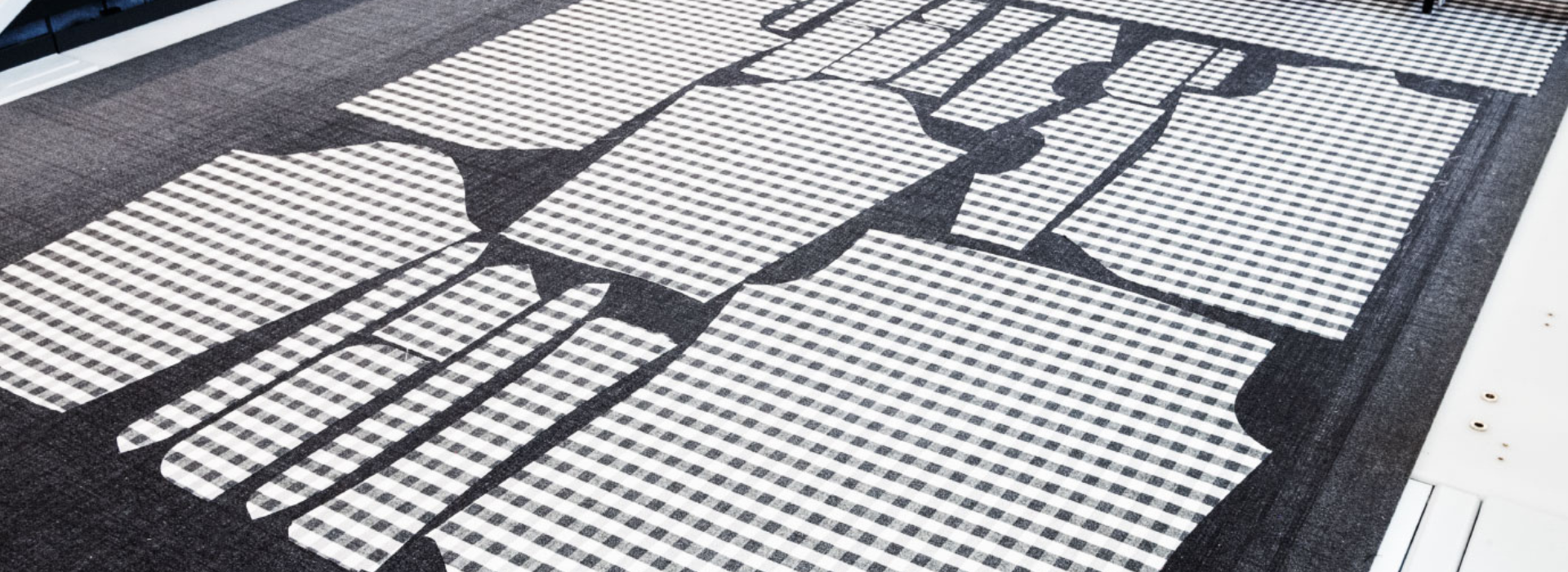

As the name suggests, single-ply cutting machines process one layer of fabric at a time. This technology is ideal for applications that require high attention to detail, such as panel matching, prints, or prototypes.

Advantages of Single-Ply Cutting Machines

- Cutting Precision and Quality

Cutting one layer at a time eliminates the risk of errors caused by the compression of stacked fabrics. This ensures flawless results. - Operational Flexibility

Ideal for custom orders, single-ply cutters allow for quick design changes without having to rework the entire production process. - Ability to Cut Difficult Materials

These machines are perfect for technical materials such as carbon fiber, leather, technical fabrics, and composites used in automotive and aerospace industries. - Smart Automation The most advanced single-ply digital cutters offer complete automation through artificial intelligence systems. They optimize both nesting and cutting processes with minimal human intervention.

Multi-Ply Cutting Machines: Efficiency and Speed for Mass Production

Multi-ply cutting machines, also known as “stack cutters” or “cutter beds,” are designed to cut multiple layers of stacked fabrics at the same time. This system is perfect for companies that need high productivity and fast processing times.

Advantages of Multi-Ply Cutting Machines

- Mass Production Capability

Multi-ply machines can cut up to 8 cm of compressed fabric, producing multiple pieces in a single production cycle. - Faster Processing Times

Multi-ply digital cutters speed up the process, increasing the number of pieces cut in less time. - Energy Efficiency and Eco-Friendliness

They consume low amounts of energy (around 5 kW), significantly reducing environmental impact. - Technological Innovation

The use of innovative materials and advanced control systems guarantees high-performance cutting with maximum precision.

Applications of Multi-Ply Cutting Machines

Multi-ply fabric cutting machines are the ideal solution for companies producing:

- Mass-produced apparel

- Industrial fabrics

- Fabric components for the automotive sector

Conclusion: Fabric Cutting Machines, a Strategic Investment for the Future of Textile Production

Choosing the most suitable fabric cutting machines for your production needs means optimizing workflow, reducing costs, and guaranteeing high-quality products for your clients. Whether you select single-ply or multi-ply systems, each solution offers specific advantages that should be carefully evaluated based on your production type.

Want to learn more about the best automatic fabric cutting systems? Contact us today! We’ll help you find the most suitable solution for your production needs.