Pattern Making for Clothing and the Home & Furniture Sector: Differences in the Workflow

Pattern making is a fundamental discipline in the creation of products in both fashion and design, applicable to both clothing and the home & furniture sector. Although these two areas share some common elements, the differences in their workflows are significant and should be taken into account to optimize production processes. In this article, we will explore the key differences in the workflow of pattern making applied to clothing and to the home & furniture sector, highlighting the specific aspects that define each field.

Workflow in Clothing Pattern Making

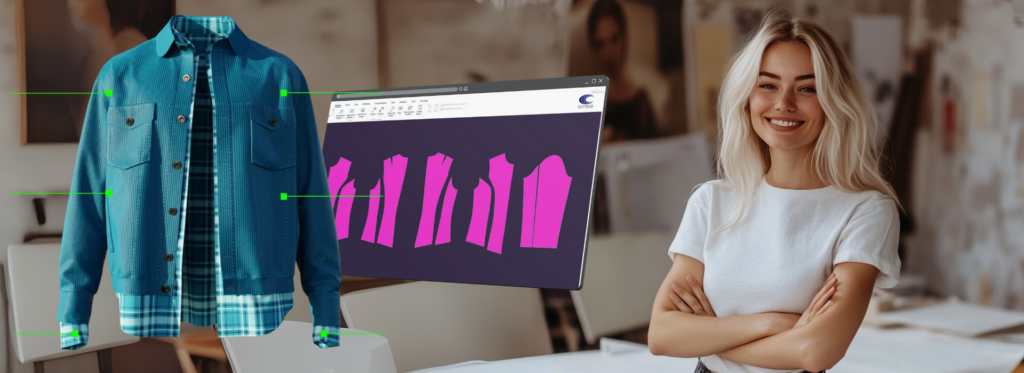

Pattern making for clothing involves the creation of patterns and prototypes for garments. In this process, the designer or pattern maker focuses on designing clothes that are both aesthetically pleasing and functional for the human body. The workflow begins with research and analysis of fashion trends, followed by sketching. Next, a pattern is created, either on paper or digitally, which will serve as the basis for the prototype.

Once the pattern is completed, the prototype is made and tested for fit and fabric quality. If necessary, changes are made to the original pattern, with subsequent testing cycles until the final garment is achieved. This process requires a high level of attention to detail and functionality in design.

Ready to improve your pattern making workflow for your sector? CLICK HERE to contact us for a personalized consultation!

Key Differences Between Pattern Making for Clothing and the Home & Furniture Sector

In the field of pattern making, there are notable differences between clothing and home & furniture design. In clothing, creating different sizes is a crucial aspect, as fit requirements vary depending on the shapes and proportions of the human body. In contrast, in furniture design, creating size variants is not necessary, as the chosen model remains constant and object dimensions are fixed.

Fabrics play a very different role in the two sectors. In clothing, pattern making requires great attention to the material’s quality, which must meet both aesthetic and functional needs, such as aligning a print, logo, or fabric pattern. Here, the placement of designs must be studied carefully. In home & furniture design, fabrics, while important, do not require the same level of complexity in design, as there are no interactions as intricate as those needed to fit the human body.

The craftsmanship also differs: in clothing, pattern making involves more complex design, particularly for the placement of pieces in specific areas of the fabric. Every detail must be considered to ensure the garment fits the body properly. In home & furniture design, on the other hand, the craftsmanship is generally more stable, and the model of the product does not require the same attention to the dynamic nature of materials or forms.

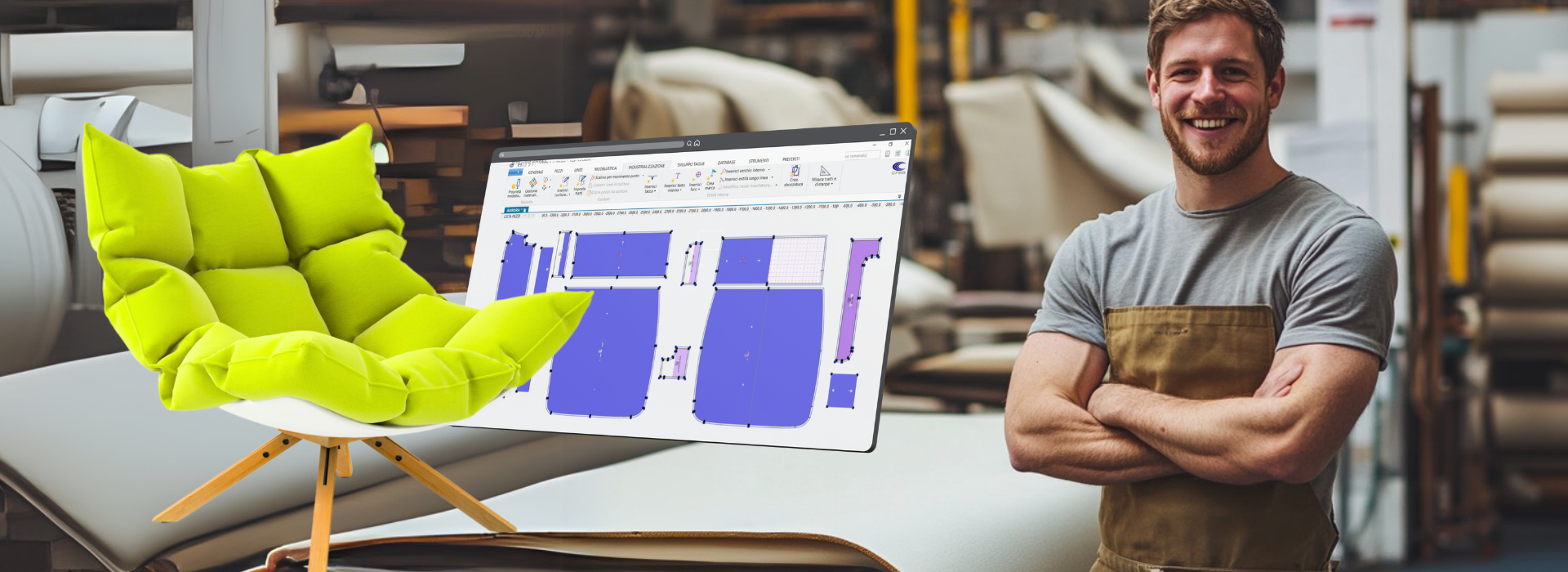

Finally, an important difference lies in the final production phase. In clothing, once the pattern is created, the fabric cutting follows a standard process, and there is no need to prepare a separate work plan before stitching, as the reference pattern is already defined. In contrast, in home & furniture design, after the pattern is made and materials are cut, it is crucial to create a detailed work plan to ensure that each part of the product is assembled correctly, without errors or variations.

In summary, pattern making in clothing and furniture design differs in terms of size management, material processing, and the approach to the final production phase. Each sector requires specific skills, but both share the goal of creating a functional and aesthetically pleasing product.

How to Optimize the Pattern Making Workflow

To optimize pattern making regardless of the sector, it is essential to adopt advanced technological tools, such as CAD systems and automated placement. These tools improve efficiency and precision in design, reducing errors and the time required to create patterns.

In pattern making, the use of CAD allows designers to create and modify drawings quickly and accurately, facilitating the analysis of shapes and product dimensions. Additionally, automated placement optimizes material usage, reducing waste and ensuring more sustainable resource management. This technology, applied in both clothing and furniture design, enables the creation of complex patterns with a level of detail that would be difficult to achieve manually.

In conclusion, for modern, cutting-edge pattern making, equipping yourself with CAD and an automated placement system is not just advantageous but essential for improving the final product’s quality and optimizing production processes.

Pattern making for clothing and the home & furniture sector has distinct workflows, but both require precision, expertise, and creativity to achieve satisfactory results. Understanding these differences and optimizing processes with the right technologies is crucial for producing high-quality products in less time. Whether you are involved in fashion or interior design, effective pattern making is the foundation of every successful project.

Want to optimize your pattern making in clothing or interior design? CLICK HERE to discover how our solutions can help you!