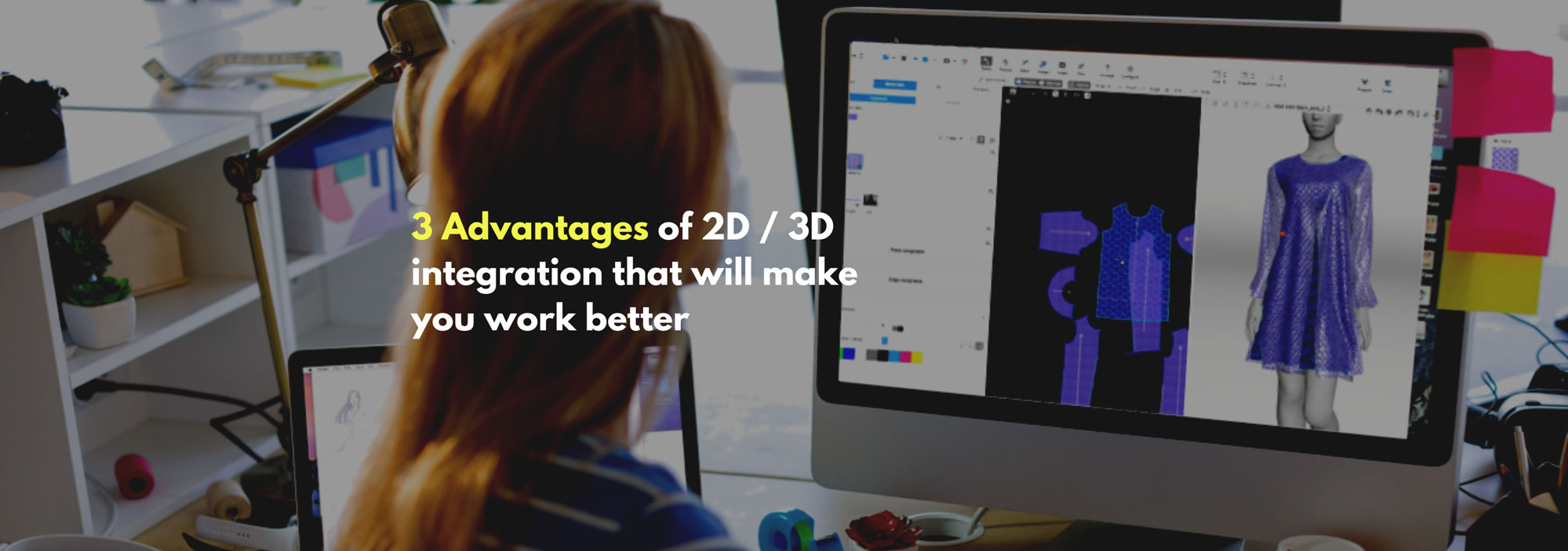

3 Advantages of 2D / 3D integration that will make you work better

The concept of gaining advantage from using a 3D CAD in terms of efforts, time-to-market and sustainability is already well consolidated. Many fashion companies are digitizing their creation and distribution processes (see : Tommy Hilfiger) to be faster to the market and more sustainable.

The element that really makes the difference rely in the integration between the working tools. If a CAD for pattern making is not well integrated with the 3D CAD the workflow couldn’t be fluid and fast, because the pattern maker will be forced to import the DXF file in the 3D for every change in the garment.

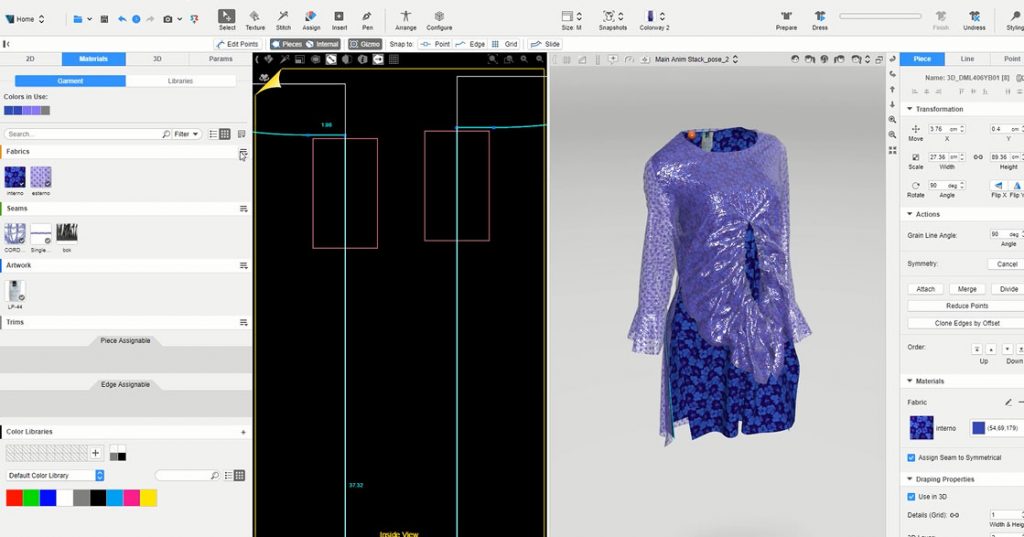

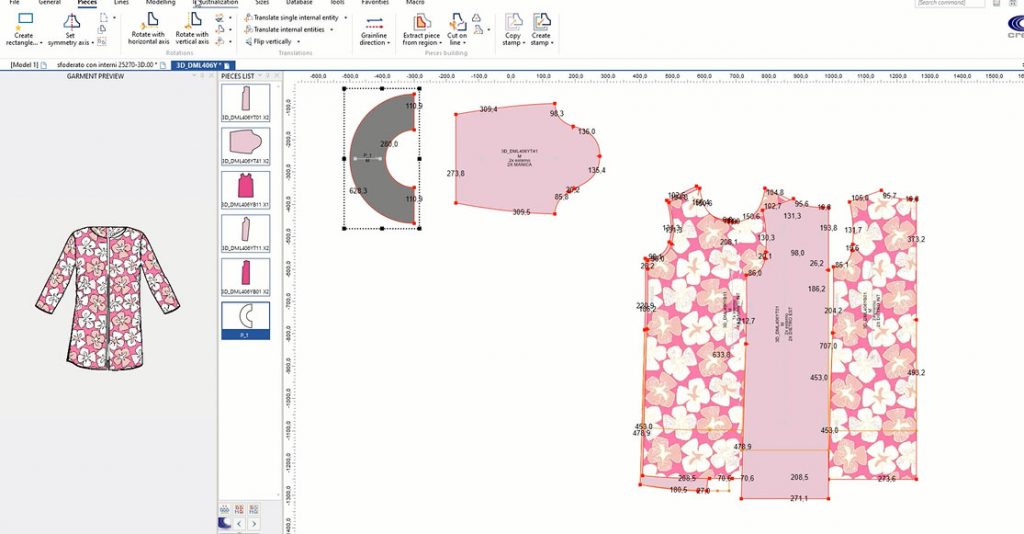

The integration between 3D CAD Browzwear and Create (2D Crea Solution CAD) allows to import every kind of 2D file format, thanks to the direct importers of proprietary formats, preserving all the pattern’s information without the need of exporting and importing DXF files.

Working with well integrated instruments let to reduce the operative time and allows to have more space for high quality activities, these are only 3 of the numerous advantages of having the 2D-3D CAD integrated :

Reducing by 30% the pattern design time

Thanks to the 2D-3D integration a single refresh is enough to observe all the changes and the fixing just done on the pattern. Observing a real-to-life prototype live-transforming at every modification of the 2D pattern is a big advantage for the pattern maker who can suddenly see the defect and immediately fix them.

If 2D and 3D CAD were not integrated the pattern maker would have to export DXF files from 2D CAD and than import such file in the 3D to see the virtual prototype, the process would be long and time-wasting.

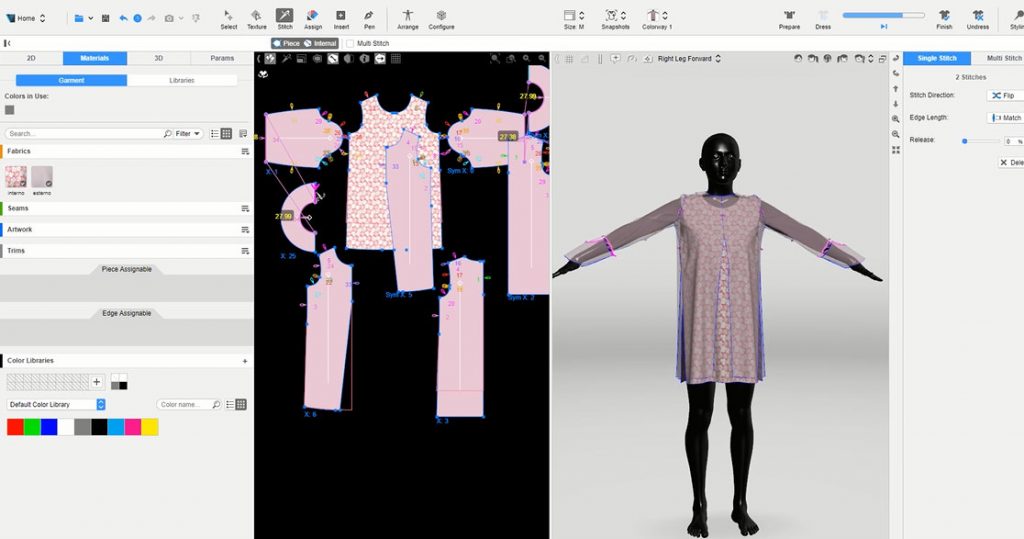

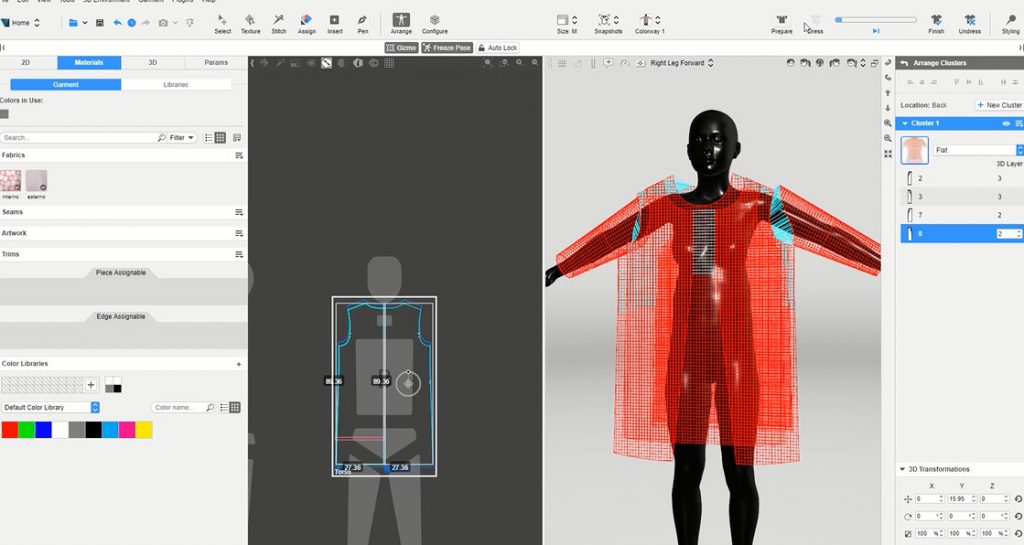

Automatic positioning of the pieces on the avatar

Trough the integration is possible to assign to the pattern pieces the position they have to take on the avatar directly during the 2D design phase, in this way the virtual dressing will be done automatically. Without such integration every time the pattern is imported the operator would have to re-position the patterns parts on the avatar, with consequential waste of time.

Garment cost forecasting before producing the first physical prototype

Once the 3D simulation is done and the material are chosen it’s possible to exploit the auto-compilation of the BOM (Bill of materials), based on the real fabric consumption, obtaining the exact cost for that garment even before producing the first physical prototype. (This feature is possible with the integration with PLM Crea Solution)